That cracked athletic track at the local high school isn’t just an eyesore. Faded lane markings, peeling surfaces, and puddles that linger for days clearly signal a track that has reached the end of its effective life. These conditions create real safety risks for athletes and community walkers alike.

A peeling surface can cause trips and falls, while a hardened, worn-out track loses its shock absorption, contributing to runner injuries. Understanding the difference between simple aging and a genuine hazard is a crucial first step. The solution isn’t always a six-figure teardown. Effective running track resurfacing can solve these issues. This guide helps you determine when to replace a running track versus when a smarter repair is the right call.

Repair, Resurface, or Replace? The 3 Levels of Fixing Your Track

A running track is best understood as a two-part system. Underneath the colorful, rubbery top is a sturdy base layer, usually asphalt, that provides the structural foundation. On top is the surface layer—the part athletes actually run on, designed to wear out over time. The condition of these two layers determines your best course of action.

If your base is solid but the surface has a few isolated gouges, a simple Repair is like patching a pothole. When the entire surface is faded and worn but the base is still sound, a Resurface is ideal. This is like putting a brand-new, protective finish on a wooden deck, restoring performance and looks without touching the foundation. This option is the most common and practical approach in athletic track maintenance.

The deep and widespread cracks, surface heaving, or ongoing drainage issues usually point to failure in the asphalt base itself. In these cases, surface-level fixes won’t last. A full replacement becomes the only viable option, requiring complete reconstruction from the ground up, beginning with proper asphalt base preparation to ensure long-term performance.

Latex vs. Polyurethane: Choosing the Right Surface for Your Budget and Needs

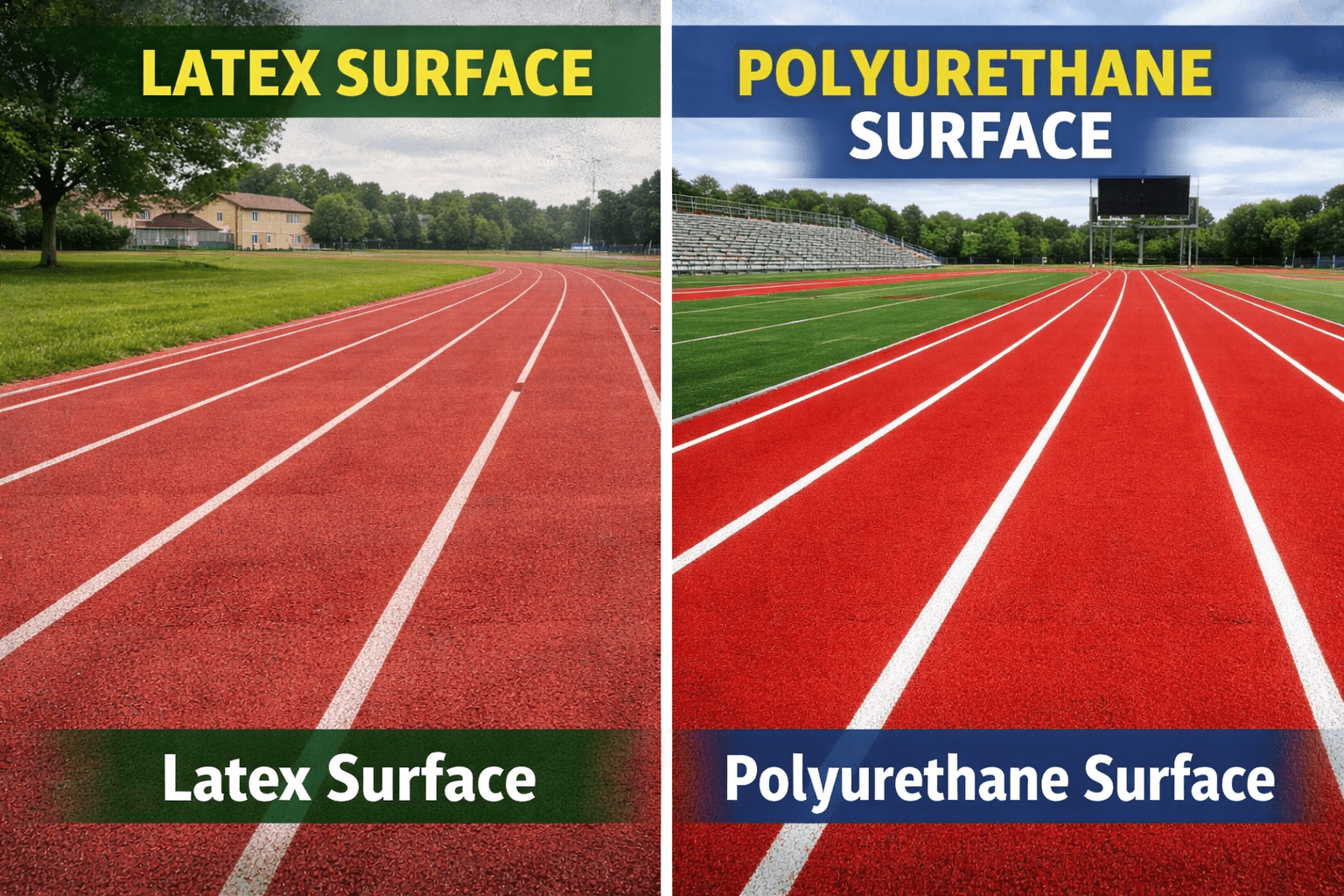

When resurfacing is the right path, the next decision is selecting the material that best fits your facility’s budget, usage level, and long-term goals. Most modern all-weather running tracks fall into two primary categories: latex and polyurethane. Think of it like choosing between standard house paint and a premium exterior coating. Both of them work, but they deliver very different levels of durability, performance, and long-term value.

Latex running track surfaces are commonly used in elementary and middle schools, community tracks, and facilities with lower daily traffic. Facility managers often choose latex because it delivers a softer, more cushioned feel underfoot, which works well for fitness activities, walking programs, and younger athletes.

Latex stands out for its lower upfront cost, making it an appealing option for organizations working within tighter budgets. However, this affordability comes with limitations. Latex surfaces typically last only five to seven years and wear down faster in high-use or competitive environments, requiring more frequent maintenance and resurfacing.

Polyurethane running track systems, by contrast, are engineered for performance and heavy use. They are the preferred choice for high schools, colleges, and competition-level facilities where speed, consistency, and energy return matter. Polyurethane surfaces feel firmer and faster, allowing athletes to generate better momentum and maintain performance.

The disadvantage of polyurethane is that the initial investment is higher. But the tracks often last eight to fifteen years or more, making them significantly more durable than latex alternatives. In many cases, the longer lifespan and reduced need for frequent resurfacing make polyurethane the better long-term investment.

Ultimately, the right choice depends on how the track will be used. Facilities choose latex when they prioritize light activity and budget control. Whereas, schools and athletic programs that demand performance, durability, and long-term cost efficiency consistently benefit from polyurethane systems. Choosing the correct sports surface from the start prevents premature resurfacing failure and protecting your investment over time.

Why Resurfacing Fails: How to Spot Bubbles, Cracks, and Puddles

Even the most advanced polyurethane surface won’t last if it’s applied over a flawed foundation. The wear and tear you see on top—like bubbles, cracks, and puddles—are often just symptoms of deeper issues. Understanding what causes these problems is key to ensuring your investment pays off.

If you spot bubbles or blisters on your track, you’re seeing clear signs of trapped moisture at work. When water vapor becomes sealed between the asphalt base and the rubber surface, it forces the layers apart, a failure known as delamination. Delamination separates the new surface from its foundation, creating weak spots that tear, peel, and fail far sooner than expected.

Likewise, large cracks and persistent puddles are red flags pointing to the base layer. A spiderweb of cracks on the surface often mirrors a failing asphalt base underneath, a problem that a simple recoat cannot fix. Puddles that stick around long after a rainstorm—a problem known as ponding—indicate the track lacks the proper slope needed for water to drain away effectively.

Before applying a single drop of new material, a quality contractor will always diagnose and repair the asphalt base first. This ensures that it’s stable, smooth, and properly sloped. This essential prep work is what guarantees a safe, durable finish and is a major factor in determining your final project cost.

How Much Does It Cost to Resurface a Track? A Realistic Budget Guide

When budgeting for your project, resurfacing is far more affordable than a full replacement. Since you’re saving the expensive asphalt foundation, a resurfacing project often costs only a fraction of starting over, preserving funds for other facility needs. The final price tag depends heavily on track size, the extent of base repairs needed, and the type of new surface you choose.

Contractors typically price running track resurfacing on a per-square-foot basis, which allows facility owners to compare options more accurately. Premium polyurethane systems carry a higher per-square-foot cost than basic latex surfaces, but that higher price often reflects increased durability and performance. In many cases, a slightly higher upfront investment delivers significantly greater long-term value.

A smarter way to measure value is by calculating the cost per year of use. A surface that costs more upfront but offers a longer track surface life expectancy—say, 15 years versus seven—can provide better long-term value. This is a critical factor to consider when evaluating proposals from contractors.

Your Next Step: Ask a Track Contractor the Right Questions

That cracked, faded track is no longer an overwhelming problem—it’s a project you are equipped to lead. You now have the clarity needed to begin a productive conversation with a professional.

Your first step is to use this knowledge to interview potential contractors. They should be able to explain the ‘why’ behind their recommended running track resurfacing solutions, demonstrating they understand your specific needs. You now see the path from a worn surface to a source of community pride. By championing smart athletic track maintenance, you’re ensuring a safe, durable, and inspiring space for everyone who uses it for years to come.